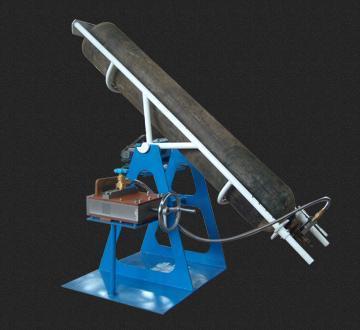

Dry Ice Blasting Machine

Product Details:

- Product Type Dry Ice Blasting Machine

- Material Stainless Steel

- Automatic Yes

- Control System PLC

- Color Sliver

- Warranty 1 Years

- Click to View more

Dry Ice Blasting Machine Price And Quantity

- 1 Unit

- 1400000 INR

Dry Ice Blasting Machine Product Specifications

- Dry Ice Blasting Machine

- PLC

- Sliver

- 1 Years

- Stainless Steel

- Yes

Dry Ice Blasting Machine Trade Information

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- As per client requirement.

- All India

Product Description

Owing vast experience of our skillful employes, we are manufacturing and supplying a wide range of Dry Ice Blasting, which are the cost effective and efficient because of its design. It is a basically an innovative cleaning technique finished by utilizing strong CO2 pellets likewise, known as dry ice which is basically utilized for mechanical use as a part of an assortment of utilization. The pellets sublimate change over straightforwardly from a strong impact pellet to a vapor (CO2) leaving no buildup and this procedure is better than sand impacting, glass dab impacting and different sorts of cleaning strategies for various reasons. Also, Dry Ice Blasting can be availed at market driving costs.

Features:

- This dry ice technique for cleaning is rapidly getting to be favored for natural and also generation reasons.

- On account of huge natural controls, industry has expected to minimize squanders.

- There is a developing cognizance that numerous are setting now on the worldwide ecological effect of their creation hones.

- These advantages are emphasized because of the gigantic execution increases through dry ice impacting - next to zero creation downtime, nature of perfect and minimized harmed to gear.

Specifications:

Dry Ice Blasting Machine Types:-

Single Hose Machines:

- IS-75S dry ice blasting unit

- IS-135S dry ice blasting unit

- IS-77S dry ice blasting unit

- Mighty - E dry ice blasting unit

- Mamba 75 dry ice blasting unit

- IS-60 dry ice blasting unit

Specification :

Dry Ice Blast Cleaning Comparison Chart

|

Blasting Cleaning Technique |

Waste for Disposal |

Abrasive |

Toxic |

Electrically Conductive |

Performance Comparison |

|

Dry Ice |

No |

No |

No |

No |

Excellent |

|

Sand |

Yes |

Yes |

No |

No |

OK |

|

Glass Beads |

Yes |

Yes |

No |

No |

OK |

|

Walnut Shells |

Yes |

Yes |

No |

No |

Limited |

|

Steam |

No |

No |

No |

Yes |

Poor |

|

Solvents |

Yes |

No |

Yes |

Yes |

Limited |

Cleaning Method Comparision :

|

Issue |

Traditional |

Dry Ice Blasting |

|

Equipment Downtime |

Cleaned in dedicated cleaning area ; Disassembly / reassembly; Drying time required |

Equipment can be cleaned in place; Dry process - equipment restart immediately after cleaning |

|

Hazardous waste |

Cleaner becomes and treated as a secondary contaminant |

No additional contaminant .Dry ice sublimates with contact with targeted surface |

|

Labor Hours |

Intensive hand scrubbing; Lengthy cleanings; Follow-up cleaning-up can be lengthy |

Dramatically reduced - often completed in a quarter of time or better |

|

Quality of Cleaning |

Poor to average |

Excellent |

|

Potential Equipment Damage |

Grit abrasions; Grit contamination; Movement of equipment to and from cleaning area |

No equipment damage; Preventive maintenance very realistic as labor hours are significantly less |

|

Safety |

Health threats from solvents; Water-based cleaning pose hazards around electrical equipment; |

Standard safety precautions; Dry process - safe around electrical equipment |

|

Cost |

Cleaner becomes additional hazardous waste; expensive solvents; |

Minimal - cost of dry ice |

Applications :

|

Airlines/Aerospace - |

Utilities |

|

Automotive |

Electrical |

|

Foundries |

Food Processing |

|

General Maintenance |

Mass Transit |

|

Marine |

Pharmaceuticals |

|

Plastics |

Printing/Plating |

|

Pulp and paper |

Rubber |